{{ $t('shop.all.spaetbestellservice.hinweis') }}

Air amplifier nozzle, 64 mm outlet, 1.4305

{{ $t('shop.all.artikelnummer') }}:

LVS 63 I ES

{{ $t('shop.all.menge') }}

{{ $t('shop.display.artikel.hinweis_alternative') }}

{{ $t('shop.display.artikel.beschreibung_headline') }}

Function:

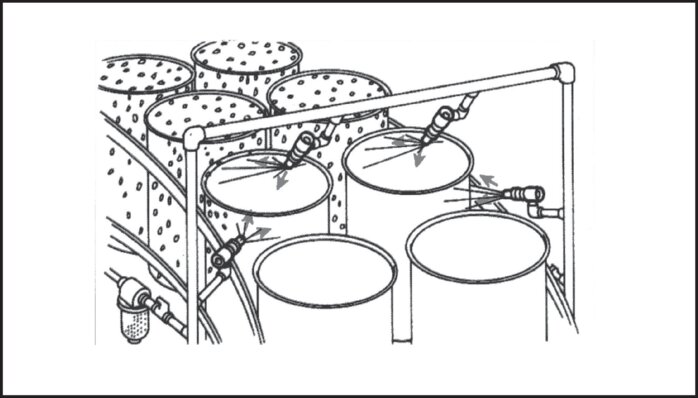

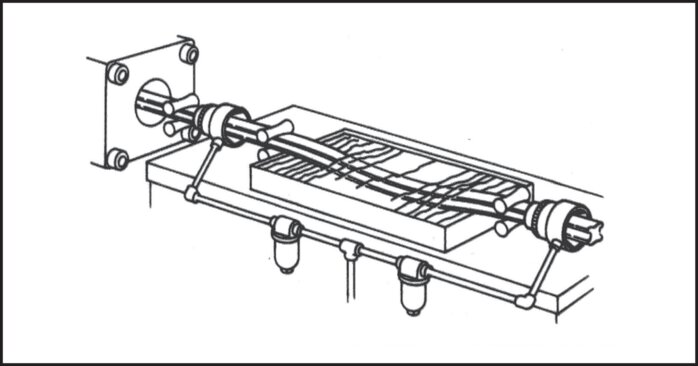

Air escapes through a thin ring gap with almost the speed of sound. During this process, ambient air is drawn along from the rear side of the amplifier, so that an intensified air jet is emitted on the front side. The air amplifiers can either be integrated in a pipe system, or used as an open system and work like a vacuum system, fan or blower for blowing of exhausting dust, exhaust gases, granulates or fibrous materials. When installed in a pipe system, at factory settings, the adjustable standard nozzles, have an amplification factor of 12 to 25:1 (as an open system: 36 to 75:1), the high-pressure nozzle 4:1 and the inline nozzles 3 to 4.5:1.

Suitable:

Air amplifiers are used where large quantities of air at low pressure are required, with minimum compressed air consumption. Adjustable nozzles can be easily matched to all application cases.

Temperature range:

-20°C to +120°C (Inline nozzles: -20°C to +80°C)

Operating pressure:

1 - 10 bar (Inline nozzles: 1 - 6 bar), optimum: 5 bar (filtered, unoiled compressed air)

Application examples:

•Transportation of all materials that can be moved by rapid gusts of air, e.g. chippings, saw dust, smoke, paper, fabric strips, pellets, dust, capsules, powder, etc.,

•Ventilating and extracting smoke and vapours without a ventilator (explosion protection),

•Removal of chippings, trimming residue, water, dust, etc.,

•Cooling cast parts and cast moulds,

•Cleaning and cooling extrusion parts that are moved through the air amplifier

Advantages:

•low air consumption - energy saving,

•significant noise reduction,

•easily adjustable air flow and pressure,

•immediate on / off behaviour,

•no electrical current, no risk of explosion,

•maintenance free,

•no moving parts - no wearing,

•low sound level

Air escapes through a thin ring gap with almost the speed of sound. During this process, ambient air is drawn along from the rear side of the amplifier, so that an intensified air jet is emitted on the front side. The air amplifiers can either be integrated in a pipe system, or used as an open system and work like a vacuum system, fan or blower for blowing of exhausting dust, exhaust gases, granulates or fibrous materials. When installed in a pipe system, at factory settings, the adjustable standard nozzles, have an amplification factor of 12 to 25:1 (as an open system: 36 to 75:1), the high-pressure nozzle 4:1 and the inline nozzles 3 to 4.5:1.

Suitable:

Air amplifiers are used where large quantities of air at low pressure are required, with minimum compressed air consumption. Adjustable nozzles can be easily matched to all application cases.

Temperature range:

-20°C to +120°C (Inline nozzles: -20°C to +80°C)

Operating pressure:

1 - 10 bar (Inline nozzles: 1 - 6 bar), optimum: 5 bar (filtered, unoiled compressed air)

Application examples:

•Transportation of all materials that can be moved by rapid gusts of air, e.g. chippings, saw dust, smoke, paper, fabric strips, pellets, dust, capsules, powder, etc.,

•Ventilating and extracting smoke and vapours without a ventilator (explosion protection),

•Removal of chippings, trimming residue, water, dust, etc.,

•Cooling cast parts and cast moulds,

•Cleaning and cooling extrusion parts that are moved through the air amplifier

Advantages:

•low air consumption - energy saving,

•significant noise reduction,

•easily adjustable air flow and pressure,

•immediate on / off behaviour,

•no electrical current, no risk of explosion,

•maintenance free,

•no moving parts - no wearing,

•low sound level

{{ $t('shop.display.artikel.eigenschaften_headline') }}

| Version | Inline nozzle, fixed setting, hose connection possible on both sides |

| Material | 1.4305 |

| Connection | G 1/2" (female thread) |

| Air consumption [m³/min] | 2,00 |

| Conveyor volumes [m³/min] | 8,7 |

| clear width [mm] | 50 |

| Pipe diameter (air inlet) [mm] | 64 |

| Pipe diameter (air outlet) [mm] | 64 |

| length [mm] | 190 |

{{ $t('shop.display.artikel.info') }} LVS63IES

| {{ $t('shop.all.gewicht') }} | 3,1 kg / pcs |

| {{ $t('shop.display.artikel.zollwarennummer') }} | 84798997 |

| {{ $t('shop.display.artikel.rohskonform') }} | {{ $t('shop.all.ja') }} |

{{ $t('shop.all.dokumente') }}

- {{ $t('shop.display.datenblatt.titel') }} ({{ $t('shop.all.englisch') }}) (Print view)

Catalogue page Atlas 9 (Page 940_n) atlas9_neutral_seiten/940_n.pdf

Documentation dokuneutral/doku_lvs_n.pdf

Documentation dokuneutral/doku_lvs_n.pdf

{{ $t('shop.all.unverbindliche_richtwerte') }}

{{ $t('shop.all.wochenendversand.hinweis') }}

An error has occurred!

An error has occurred, please reload this page and try again.